I am getting ready to fly back to the U.S. after another successful factory trip. As of today, we have completed the first container load of molded bases! Now they just need to be assembled...

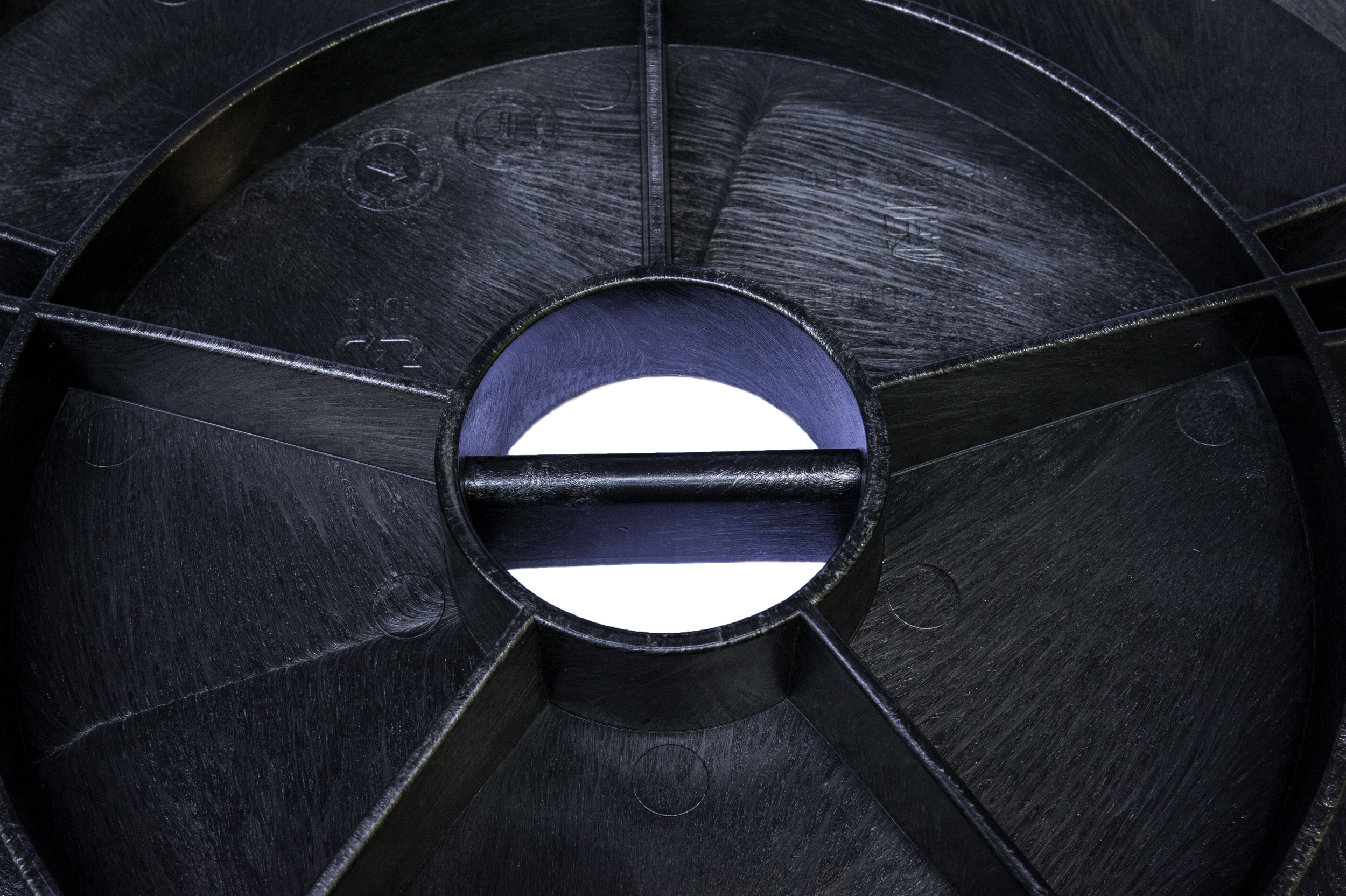

One of my goals when I arrived here was to confirm that the casters ordered were the ones received. Check. The next factor that is critical is that the casters must be installed in the correct configuration. One of the really neat features of this tire dolly is the ease with which it can be steered. Check out the video of the 4 year old steering a load of tires around some cones and you will see what I mean. The reason that works is because two of the five casters are mounted parallel to each other and they are rigid, non-swivel. It just won't do to have those installed in the wrong positions! We have confirmed an assembly line setup that will make that as humanly fool-proof as possible. Check. The next thing I was concerned about is that proper torque is applied to the screws that hold those casters in place. HDPE material is soft and flexible. We could not have installers with heavy air tools twisting those screws right past design specs. We were able to specify tools that would limit this tendency and Quality Control procedures to check that the tools remain accurate. Check. Lastly, we needed to make sure we had the perimeter decal created out of durable material that could also be removed by the end user if desired. Those will be done today, alas, after I have gone home. Semi-Check.

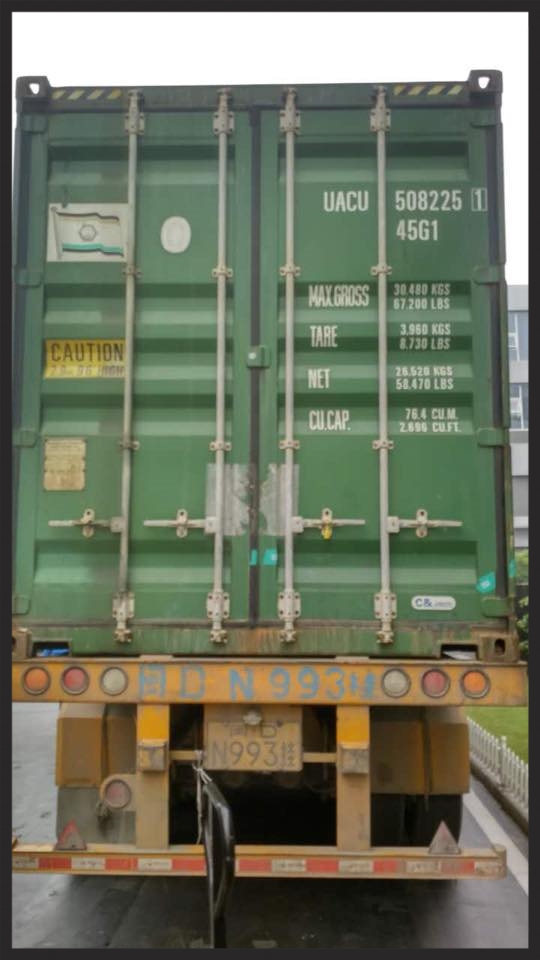

All in all, a very good trip. We have been hoping for a delivery to the U.S. prior to the end of the year. We are still on track for that, but barely. I have been assured that all casters will be installed on the first 1250 units by next Saturday the 19th. They will be boxed and shipped immediately on completion, so if the boat is fast enough, and we clear customs in Oakland fast enough, we should be able to fulfill orders the first week of January as promised.

Going to catch a plane!